Hoc consilio in mente habentes, inter fabricatores Sinenses, qui "S355jh 48 unciarum nigrarum ferrearum tubarum," "tubum ferreum carbonicum sine suturis," numeramur et novissimi technologice, et pretio competitivo, facti sumus. In futurum spectantes, longa via adhuc est, constanter contendentes ut omnes operarii pleno studio, centuplo fiducia, societate nostra pulchrum ambitum, producta provecta, qualitatem primae classis, modernam societatem aedificavimus, et diligenter laboramus!

Hoc motto in mente habentes, inter fabricatores technologice innovativos, sumptibus parcissimos, et pretio competitivissimos facti sumus.Tubus Chalybis Carbonis Sinensis, Tubus FerreusCum progressu societatis et oeconomiae, societas nostra spiritum "fidelitatis, dedicationis, efficientiae, innovationis" incepti continuabit, et semper adhaerebimus notioni administrativae "malo aurum amittere, non animum clientium amittere". Negotiatoribus domesticis et externis sincera dedicatione serviemus, et nobis permittemus ut una vobiscum futurum splendidum creemus!

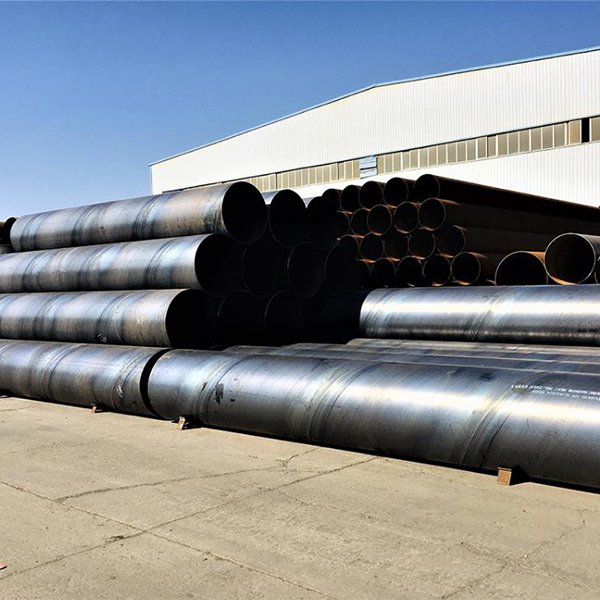

Tubus Ferreus SSAW

| Diameter Externus OD | 219mm-3500mm |

| Crassitudo muri | 1.5mm-25mm |

| Longitudo | 3-18M |

| Superficies | Nuda, leviter oleata, nigra picta, tegumentum anticorrosionis (FBE / 2PE / 3PE) |

| Sarcinatio | In mole, protector extremitatum utrinque, materiis aquae resistentibus involutis |

| Applicatio | Tubus aquarius, pali ferrei, tubi olei et gasi, fistulae ferreae, etc. |

Specificationes producti

| Classificatio | Norma | Producta Praecipua |

| Tubus Ferreus ad Servitium Fluidorum | GB/T 14291 | Tubus conglutinatus ad usum fluidorum fodinarum |

| GB/T 3091 | Tubus conglutinatus ad usum fluidorum pressionis humilis |

| SY/T 5037 | Tubus ferreus arcu submersus spiraliter sudatus ad usum fistularum ad fluidorum pressione humili |

| ASTM A53 | Tubus ferreus niger et calido-coxis galvanizatus, sudatus et sine suturis |

| BS EN10217-2 | Tubi ferrei ad usum pressionis conglutinati – condiciones technicae traditionis – pars 2: Tubi ferrei non-mixti et mixti electrice conglutinati cum proprietatibus specificatis ad temperaturam elevatam |

| BS EN10217-5 | Tubi ferrei ad usum pressionis conglutinati – condiciones technicae traditionis – pars 5: tubi ferrei non-combinati et combinati arcu submerso conglutinati cum proprietatibus specificatis temperaturae elevatae |

| Tubus Ferreus pro Structura Ordinaria | GB/T 13793 | Tubus ferreus longitudinaliter resistentia electrica sudatus |

| SY/T 5040 | Pali tuborum ferreorum arcu spiraliter submersorum sudati |

| ASTM A252 | Pali tuborum ferreorum conglutinatorum et sine suturis |

| BS EN10219-1 | Sectiones cavae structurales frigidae formatae et sudatae ex chalybe non mixto et grano tenui – pars 1: Conditiones traditionis technicae |

| BS EN10219-2 | Sectiones cavae structurales frigidae, sudatae, ex chalybe non mixto et grano tenui – pars 2: tolerantiae, dimensiones et proprietates sectionum |

| Tubus Linearis | GB/T 9711.1 | Tubus ferreus ad systema translationis fistularum industriarum petrolei et gasi naturalis (tubus ferreus Classis A) |

| GB/T 9711.2 | Tubus ferreus ad systema translationis fistularum industriarum petrolei et gasi naturalis (tubus ferreus Classis B) |

| API 5L PSL1/2 | Tubus linearis |

| Involucrum | API 5CT/ ISO 11960 PSL1 | Tubus ferreus ad usum ut involucrum vel tubum puteorum industriarum petrolei et gasi naturalis |

Analysis Chemica et Proprietates Mechanicae

| Norma | Gradus | Compositio Chemica (max)% | Proprietates Mechanicae (min) |

| C | Si | Mn | P | S | Robur tensile (Mpa) | Robur Cessationis (Mpa) |

| API 5CT | h40 | - | - | - | - | 0.030 | 417 | 417 |

| J55 | - | - | - | - | 0.030 | 517 | 517 |

| K55 | - | - | - | - | 0.030 | DCLV | DCLV |

| API 5L PSL1 | A | 0.22 | - | 0.90 | 0.030 | 0.030 | 335 | 335 |

| B | 0.26 | - | 1.20 | 0.030 | 0.030 | 415 | 415 |

| X42 | 0.26 | - | 1.30 | 0.030 | 0.030 | 415 | 415 |

| X46 | 0.26 | - | 1.40 | 0.030 | 0.030 | 435 | 435 |

| X52 | 0.26 | - | 1.40 | 0.030 | 0.030 | 460 | 460 |

| X56 | 0.26 | - | 1.40 | 0.030 | 0.030 | 490 | 490 |

| X60 | 0.26 | - | 1.40 | 0.030 | 0.030 | 520 | 520 |

| X65 | 0.26 | - | 1.45 | 0.030 | 0.030 | 535 | 535 |

| X70 | 0.26 | - | 1.65 | 0.030 | 0.030 | 570 | 570 |

| API 5L PSL2 | B | 0.22 | 0.45 | 1.20 | 0.025 | 0.015 | 415 | 415 |

| X42 | 0.22 | 0.45 | 1.30 | 0.025 | 0.015 | 415 | 415 |

| X46 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 435 | 435 |

| X52 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 460 | 460 |

| X56 | 0.22 | 0.45 | 1.40 | 0.025 | 0.015 | 490 | 490 |

| X60 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 520 | 520 |

| X65 | 0.12 | 0.45 | 1.60 | 0.025 | 0.015 | 535 | 535 |

| X70 | 0.12 | 0.45 | 1.70 | 0.025 | 0.015 | 570 | 570 |

| X80 | 0.12 | 0.45 | 1.85 | 0.025 | 0.015 | DCXXV | DCXXV |

| GB/T 9711.1 | L210 | - | - | 0.90 | 0.030 | 0.030 | 335 | 335 |

| L245 | - | - | 1.15 | 0.030 | 0.030 | 415 | 415 |

| L290 | - | - | 1.25 | 0.030 | 0.030 | 415 | 415 |

| L320 | - | - | 1.25 | 0.030 | 0.030 | 435 | 435 |

| L360 | - | - | 1.25 | 0.030 | 0.030 | 460 | 460 |

| L390 | - | - | 1.35 | 0.030 | 0.030 | 490 | 490 |

| L415 | 0.26 | - | 1.35 | 0.030 | 0.030 | 520 | 520 |

| L450 | 0.26 | - | 1.40 | 0.030 | 0.030 | 535 | 535 |

| L485 | 0.23 | - | 1.60 | 0.030 | 0.030 | 570 | 570 |

| GB/T3091/SY/T503 | Q195 | 0.12 | 0.30 | 0.50 | 0.035 | 0.040 | CCCXV | CCCXV |

| Q215B | 0.15 | 0.35 | 1.20 | 0.045 | 0.045 | 335 | 335 |

| Q235B | 0.20 | 0.35 | 1.40 | 0.045 | 0.045 | 370 | 370 |

| Q345B | 0.20 | 0.50 | 1.70 | 0.035 | 0.035 | 470 | 470 |

| ASTM A53 | A | 0.25 | 0.10 | 0.95 | 0.050 | 0.045 | 330 | 330 |

| B | 0.30 | 0.10 | 1.20 | 0.050 | 0.045 | 415 | 415 |

| ASTM A252 | 1 | - | - | - | 0.050 | - | 345 | 345 |

| 2 | - | - | - | 0.050 | - | 414 | 414 |

| 3 | - | - | - | 0.050 | - | 455 | 455 |

| EN10217-1 | P195TR1 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P195TR2 | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235TR1 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P235TR2 | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265TR1 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 |

| P265TR2 | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 |

| EN10217-2 | P195GH | 0.13 | 0.35 | 0.70 | 0.025 | 0.020 | 320 | 320 |

| P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 |

| EN10217-5 | P235GH | 0.16 | 0.35 | 1.20 | 0.025 | 0.020 | 360 | 360 |

| P265GH | 0.20 | 0.40 | 1.40 | 0.025 | 0.020 | 410 | 410 |

| EN10219-1 | S235JRH | 0.17 | - | 1.40 | 0.040 | 0.040 | 360 | 360 |

| S275JOH | 0.20 | - | 1.50 | 0.035 | 0.035 | 410 | 410 |

| S275J2H | 0.20 | - | 1.50 | 0.030 | 0.030 | 410 | 410 |

| S355JOH | 0.22 | 0.55 | 1.60 | 0.035 | 0.035 | 470 | 470 |

| S355J2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 |

| S355K2H | 0.22 | 0.55 | 1.60 | 0.030 | 0.030 | 470 | 470 |

Tolerantia Diametri Externi et Crassitudinis Muri

| Norma | Tolerantia Corporis Tubi | Tolerantia Finis Tubi | Tolerantia Crassitudinis Muri |

| Diameter Externus | Tolerantia | Diameter Externus | Tolerantia |

| GB/T3091 | Diametros exterior ≤ 48.3 mm | ≤±0.5 | Diametros exterior ≤ 48.3 mm | - | ≤±10% |

| 48.3 | ≤±1.0% | 48.3 | - |

| 273.1 | ≤±0.75% | 273.1 | -0.8~+2.4 |

| Diameter externus > 508 mm | ≤±1.0% | Diameter externus > 508 mm | -0.8~+3.2 |

| GB/T9711.1 | Diametros exterior ≤ 48.3 mm | -0.79~+0.41 | - | - | OD≤73 | -12.5%~+20% |

| 60.3 | ≤±0.75% | Diametros exterior ≤ 273.1 mm | -0.4~+1.59 | 88.9≤OD≤457 | -12.5%~+15% |

| 508 | ≤±1.0% | OD ≥323.9 | -0.79~+2.38 | OD≥508 | -10.0%~+17.5% |

| Diameter externus (OD) > 941mm | ≤±1.0% | - | - | - | - |

| GB/T9711.2 | sexaginta | ±0.75%D ~ ±3mm | sexaginta | ±0.5%D ~ ±1.6mm | 4mm | ±12.5%T ~ ±15.0%T |

| DCX | ±0.5%D ~ ±4mm | DCX | ±0.5%D ~ ±1.6mm | Pondus ≥ 25mm | -3.00mm ~ +3.75mm |

| Diameter externus (OD) > 1430mm | - | Diameter externus (OD) > 1430mm | - | - | -10.0%~+17.5% |

| SY/T5037 | Diametros exterior <508mm | ≤±0.75% | Diametros exterior <508mm | ≤±0.75% | Diametros exterior <508mm | ≤±12.5% |

| Diametros exterior ≥ 508 mm | ≤±1.00% | Diametros exterior ≥ 508 mm | ≤±0.50% | Diametros exterior ≥ 508 mm | ≤±10.0% |

| API 5L PSL1/PSL2 | OD<60.3 | -0.8mm ~ +0.4mm | OD≤168.3 | -0.4mm ~ +1.6mm | Pondus ≤ 5.0 | ≤±0.5 |

| 60.3≤OD≤168.3 | ≤±0.75% | 168.3 | ≤±1.6mm | 5.0 | ≤±0.1T |

| 168.3 | ≤±0.75% | DCX | ≤±1.6mm | T≥15.0 | ≤±1.5 |

| DCX | ≤±4.0mm | OD>1422 | - | - | - |

| OD>1422 | - | - | - | - | - |

| API 5CT | OD<114.3 | ≤±0.79mm | OD<114.3 | ≤±0.79mm | ≤-12.5% |

| OD ≥114.3 | -0.5% ~ 1.0% | OD ≥114.3 | -0.5% ~ 1.0% | ≤-12.5% |

| ASTM A53 | ≤±1.0% | ≤±1.0% | ≤-12.5% |

| ASTM A252 | ≤±1.0% | ≤±1.0% | ≤-12.5% |

Exhibitio Producti

Hoc consilio in mente habentes, inter fabricatores Sinenses, qui "S355jh 48 unciarum nigrarum ferrearum tubarum," "tubum ferreum carbonicum sine suturis," numeramur et novissimi technologice, et pretio competitivo, facti sumus. In futurum spectantes, longa via adhuc est, constanter contendentes ut omnes operarii pleno studio, centuplo fiducia, societate nostra pulchrum ambitum, producta provecta, qualitatem primae classis, modernam societatem aedificavimus, et diligenter laboramus!

Provisor SinensisTubus Chalybis Carbonis Sinensis, Tubus FerreusCum progressu societatis et oeconomiae, societas nostra spiritum "fidelitatis, dedicationis, efficientiae, innovationis" incepti continuabit, et semper adhaerebimus notioni administrativae "malo aurum amittere, non animum clientium amittere". Negotiatoribus domesticis et externis sincera dedicatione serviemus, et nobis permittemus ut una vobiscum futurum splendidum creemus!

Praecedens: fistula ferrea carbonica sine suturis Deinde: Tubus Ferreus Niger S355jh 48 Pollices, Tubus Carbonis Sinensis Sinensis, Tubus Ferreus Consutabilis, Provisor Sinensis